For modern production, efficiency is one of the most important factors of sustainable development. Efficiency is a multifaceted concept and at the same time quite specific.

"... the VSP project approach, based on the possibility of choice, allows us to offer the user the optimal solution based on specialized requirements, with account of quality and compliance with standards."

In today's highly competitive and volatile market, logistics solutions and pricing flexibility are also important components of efficiency. The optimal VSP solution represents the most effective solution to a technical problem, one of high-quality, on time and at a competitive market price. These provisions are embedded in our project approach and are supported by real activities of VSP.

HAVI Engineering India Pvt. Ltd. (former Vipal Enterprises Pvt Ltd.) ) was incorporated in Mumbai, India in 2007. The company's experience in the field of instrumentation products is backed by a manufacturing expertise in OEM market since 1965. HAVI Engineering manufactures and supplies products to more than 20 countries around the world and is an authorized supplier to a number of large international oil & gas and oil refining companies, as well as end users in the Middle East and Asian region.

HAVI Engineering India Pvt. Ltd. (former Vipal Enterprises Pvt Ltd.) ) was incorporated in Mumbai, India in 2007. The company's experience in the field of instrumentation products is backed by a manufacturing expertise in OEM market since 1965. HAVI Engineering manufactures and supplies products to more than 20 countries around the world and is an authorized supplier to a number of large international oil & gas and oil refining companies, as well as end users in the Middle East and Asian region.

The new VSP supplier of Instrumentation products, HAVI Engineering company, will provide for higher efficiency of VSP project solutions for users, taking into account affordable pricing and compliance with international, Russian and industry standards.

The goal is not to redistribute the shares of different VSP suppliers in the Instrumentation products portfolio, but to increase the overall volume of business and improve the return on one of the main areas of the company operation in the market.

VSP has more than 25 years of expertise in the industrial automation market, including Instrumentation products. We work with Rosneft production facilities; machine-building enterprises; at Lukoil, Sibur, Eurochem, Taneco sites ... Solutions by VSP suppliers are also used in projects of such companies as ABB, Honeywell, Yokogawa, Basf, Air Liquide, BP, Cinopec, Statoil, Shell and other international projects.

Knowledge and analysis of the market, understanding of the actual operational expectations and requirements of customers are at the heart of VSP business solutions. Our experience and professional contacts with end users and manufacturing companies provide a 360° view of the market. A company independent of any manufacturer, VSP analyzes the customer's requirements in the first place, since successful cooperation with the end user is ultimately beneficial for VSP as well.

A variety of tasks, ways to solve them, project terms and conditions and a budget framework largely determine the choice of a product by a specific manufacturer when working with the customer. The decision to include HAVI products in the VSP portfolio of possible offers in Instrumentation products line is also grounded on some history.

Along with studying the company's products, comprehensively analyzing requirements of the Russian market with unconditional reliability requirements, as well as price characteristics, an important stage was marked by a visit of VSP representatives to HAVI in India. This allowed us to see the production sites with our own eyes, get acquainted with production equipment, test benches, and operational procedures. Meetings with specialists and management of HAVI demonstrated the company interest in working in the Russian market. Regular contacts and video conferences of VSP and HAVI specialists make it possible today to promptly resolve current issues.

VSP has more than 25 years of expertise in the industrial automation market, including Instrumentation products. We work with Rosneft production facilities; machine-building enterprises; at Lukoil, Sibur, Eurochem, Taneco sites ... Solutions by VSP suppliers are also used in projects of such companies as ABB, Honeywell, Yokogawa, Basf, Air Liquide, BP, Cinopec, Statoil, Shell and other international projects.

Knowledge and analysis of the market, understanding of the actual operational expectations and requirements of customers are at the heart of VSP business solutions. Our experience and professional contacts with end users and manufacturing companies provide a 360° view of the market. A company independent of any manufacturer, VSP analyzes the customer's requirements in the first place, since successful cooperation with the end user is ultimately beneficial for VSP as well.

A variety of tasks, ways to solve them, project terms and conditions and a budget framework largely determine the choice of a product by a specific manufacturer when working with the customer. The decision to include HAVI products in the VSP portfolio of possible offers in Instrumentation products line is also grounded on some history.

Along with studying the company's products, comprehensively analyzing requirements of the Russian market with unconditional reliability requirements, as well as price characteristics, an important stage was marked by a visit of VSP representatives to HAVI in India. This allowed us to see the production sites with our own eyes, get acquainted with production equipment, test benches, and operational procedures. Meetings with specialists and management of HAVI demonstrated the company interest in working in the Russian market. Regular contacts and video conferences of VSP and HAVI specialists make it possible today to promptly resolve current issues.

HAVI Instrumentation products cover fittings and connectors of various types; valves of various types and applications; manifolds, monoflanges, and integrated valves. Products are available with NACE compliant options and oxygen cleaned. Products come in a variety of standard materials and packing options. HAVI range also includes air distribution manifolds and different piping accessories; prefabricated hookups for flow and pressure metering at high and low temperatures, including cryogenic systems, mounting accessories etc.

Customers and Industries.

HAVI is an authorized supplier to a number of major oil & gas and oil refining companies in the Middle East and Asia region, such as ADGAS, TAKREER, BOROUG, PETRONAS, major refineries in India — Essar Oil, Reliance Energy, Cairns Energy and others. HAVI customers also include DCS companies — ABB, Yokogawa; and EPC companies, for example, Larsen & Toubro Ltd., Toyo, UHDE.

Favourable infrastructure, a modern machine park, a testing program and 100% output control allow HAVI to manufacture high-quality serial instrumentation products for the oil & gas industry, chemistry and petrochemistry, for railway transportation and the automotive industry, for the production of fertilizers.

Favourable infrastructure, a modern machine park, a testing program and 100% output control allow HAVI to manufacture high-quality serial instrumentation products for the oil & gas industry, chemistry and petrochemistry, for railway transportation and the automotive industry, for the production of fertilizers.

Certified Quality.

HAVI Engineering products are manufactured meeting the requirements of internationally recognised standards: ISO 9001:2015, PED 97/23/EC, CE Marking, AD Merkblatt; with strict Quality Control requirements complying with Fire Test API 607, BS 4368 Pt. IV, ASTM F 1387, MSS SP 99. At present preparation is actively progressing for HAVI Engineering certification in Russia.

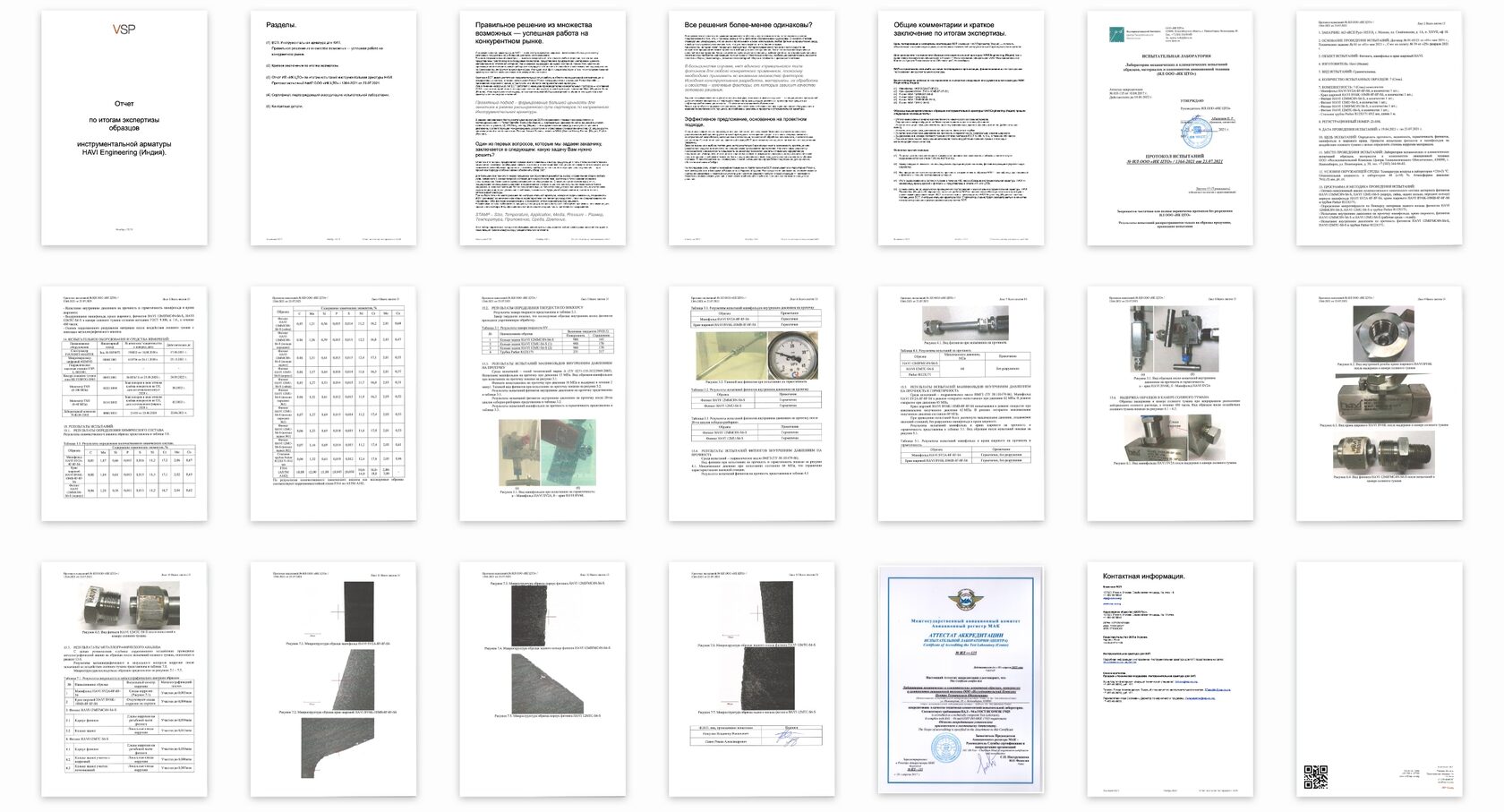

The standard VSP practice is to conduct independent testing of our suppliers' solutions by accredited Russian organizations. The purpose of testing and assessment of the VSP supplier products is to obtain an objective and independent evaluation of the quality factors of the manufacturer's instrumentation products. A similar approach has also been taken to HAVI products.

The list of HAVI products for testing and assessment included samples of manifolds, ball valves and various fittings.

The main tests included:

- Optical emission analysis of the quantitative chemical composition of the material;

- Determination of the Vickers microhardness of the material of the rear fitting ring;

- Internal pressure test for leakage of the manifold, ball valve, fittings (working medium - helium);

- Internal pressure strength test of fittings and tubes;

- Internal pressure strength and leak test of the manifold and ball valve;

- Holding in the salt mist chamber according to the GOST 9.308 procedure, item 1.6., for 480 hours;

- Assessment of the corrosion damage of the material after exposure to salt mist using metallographic analysis.

The results of the chemical composition test of the samples fully confirmed the manufacturer's specification of the manufacturing material — corrosion-resistant steel F316 according to ASTM A182.

The hardness measurement showed that the studied samples of the inner rings of the fittings underwent hardening treatment.

All HAVI samples submitted for strength and leak tests — manifold, ball valve and fittings — have passed tests successfully.

The results of holding samples of HAVI products in salt mist for 480 hours — manifold, ball valve and fittings — are presented in the report.

The standard VSP practice is to conduct independent testing of our suppliers' solutions by accredited Russian organizations. The purpose of testing and assessment of the VSP supplier products is to obtain an objective and independent evaluation of the quality factors of the manufacturer's instrumentation products. A similar approach has also been taken to HAVI products.

The list of HAVI products for testing and assessment included samples of manifolds, ball valves and various fittings.

The main tests included:

- Optical emission analysis of the quantitative chemical composition of the material;

- Determination of the Vickers microhardness of the material of the rear fitting ring;

- Internal pressure test for leakage of the manifold, ball valve, fittings (working medium - helium);

- Internal pressure strength test of fittings and tubes;

- Internal pressure strength and leak test of the manifold and ball valve;

- Holding in the salt mist chamber according to the GOST 9.308 procedure, item 1.6., for 480 hours;

- Assessment of the corrosion damage of the material after exposure to salt mist using metallographic analysis.

The results of the chemical composition test of the samples fully confirmed the manufacturer's specification of the manufacturing material — corrosion-resistant steel F316 according to ASTM A182.

The hardness measurement showed that the studied samples of the inner rings of the fittings underwent hardening treatment.

All HAVI samples submitted for strength and leak tests — manifold, ball valve and fittings — have passed tests successfully.

The results of holding samples of HAVI products in salt mist for 480 hours — manifold, ball valve and fittings — are presented in the report.

Compliance with international standards, the results of examination and a number of tests conducted by VSP on the basis of a specialized Russian laboratory allow us to include HAVI solutions in VSP projects, where the application of HAVI will fully meet technical requirements of the customer and will be optimal from a commercial point of view.

HAVI Tube Fittings.

Compression fittings — single and double fittings, elbows, bulkhead etc. Available in sizes up to 1/16" -1 1/2" (3-28 mm). Working pressure up to 6 000 psi.

Connectors — straight union, reducer union, bulkhead union, union tee etc. Connectors are available with the choice of threads and in sizes up to 1/16" - 2". Working pressure up to 10 000 psi. MWP Type tested to ASTM F 1387.

Hydraulic fittings — JIC fittings, cutting ring fittings, cross fittings and other various configurations. Available in sizes 1/8" - 1". Hydraulic fittings of various configuration are available for pressure up to 5 000 psi.

HAVI tube fittings are designed to compensate variation in tubing materials, hardness and wall thickness and allow for repeated remake. These fittings are available for fractional and metric tubes with the choice of pipe threads NPT, BSP/BSPT, SAE/MS. Materials of construction include stainless and carbon steel, brass, alloy M400, C276, titanium, PTFE etc.

Quality control at all stages of design and manufacture provide for interchangeability with a third party brands. When intermixed with other brands reliability of operation is assured.

Connectors — straight union, reducer union, bulkhead union, union tee etc. Connectors are available with the choice of threads and in sizes up to 1/16" - 2". Working pressure up to 10 000 psi. MWP Type tested to ASTM F 1387.

Hydraulic fittings — JIC fittings, cutting ring fittings, cross fittings and other various configurations. Available in sizes 1/8" - 1". Hydraulic fittings of various configuration are available for pressure up to 5 000 psi.

HAVI tube fittings are designed to compensate variation in tubing materials, hardness and wall thickness and allow for repeated remake. These fittings are available for fractional and metric tubes with the choice of pipe threads NPT, BSP/BSPT, SAE/MS. Materials of construction include stainless and carbon steel, brass, alloy M400, C276, titanium, PTFE etc.

Quality control at all stages of design and manufacture provide for interchangeability with a third party brands. When intermixed with other brands reliability of operation is assured.

HAVI Needle Valves.

HAVI Bar Stock Needle Valves are manufactured from Bar Stock, are available in sizes 1/4"-1", and are 100% factory tested in accordance with BS EN 12266-1. Depending on the series the working pressure is 6 000 to 10 000 psi.

Forged Needle Valves series work on pressures from 3 000 psi and are provided with PTFE packing. Thread rolled and burnished stem provide for precise regulation of the flow.

Forged Needle Valves series work on pressures from 3 000 psi and are provided with PTFE packing. Thread rolled and burnished stem provide for precise regulation of the flow.

HAVI Check and Bleed Valves.

Check valves are available with 8 configurations of spring rates, for pressures up to 6 000 psi, and temperatures up to 204 ℃.

Bleed valves are used on instrumentation devices such as multivalve manifolds or gauge valves to vent signal line pressure to atmosphere before removal of an instrument or to assist in calibration of control devices. Working pressure of 10 000 psi.

Available in sizes 1/8"-1".

Bleed valves are used on instrumentation devices such as multivalve manifolds or gauge valves to vent signal line pressure to atmosphere before removal of an instrument or to assist in calibration of control devices. Working pressure of 10 000 psi.

Available in sizes 1/8"-1".

HAVI Ball Valves.

Configurations cover 2- and 3-way valves of compact design allowing for working pressures up to 10 000 psi in the range of temperatures from -54 to 260 ℃. Available in sizes 1/4"-1".

High pressure valves are suitable for panel mounting applications. Depending on the application and series oxygen cleaning is provided. Superfinish ball allows for effective sealing.

High pressure valves are suitable for panel mounting applications. Depending on the application and series oxygen cleaning is provided. Superfinish ball allows for effective sealing.

HAVI Manifolds, Monoflange Valves, Integrated Valves.

Manifold valves by HAVI are designed and manufactured for multiple applications for isolation, calibration, testing of pressure instruments. The manifolds are available in the configuration of 2- valve, 3-valve and 5-valve. Various material options for body and packing are available for different temperature applications. Non-rotating design of the tip prevents seat wear. Working pressure is up to 10 000 psi. Manifolds are available in sizes 1/4"-2".

SBB and DBB monoflange series are designed to provide compact installation of gauges and other transmitter instruments. Monoflange manifolds are used as an alternative to standard multi valve system. They allow for considerable cutdown in potential leak paths, help to reduce the weight of the system and mechanical stress due to vibration. The working pressure is up to 6 000 psi, available in sizes up to 2".

Integral valves are used in block & bleed applications, double block included, all the valves are integrated in one piece. The valves come in different configurations and combinations. Integral valves can be mounted directly on flanges. The main advantage of the valves is the reduction of weight and leak path due to vibration. The working pressure is up to 6 000 psi.

SBB and DBB monoflange series are designed to provide compact installation of gauges and other transmitter instruments. Monoflange manifolds are used as an alternative to standard multi valve system. They allow for considerable cutdown in potential leak paths, help to reduce the weight of the system and mechanical stress due to vibration. The working pressure is up to 6 000 psi, available in sizes up to 2".

Integral valves are used in block & bleed applications, double block included, all the valves are integrated in one piece. The valves come in different configurations and combinations. Integral valves can be mounted directly on flanges. The main advantage of the valves is the reduction of weight and leak path due to vibration. The working pressure is up to 6 000 psi.

Other solutions by HAVI.

Other solutions include condensate pots; air distribution manifolds; prefabricated hookups; mounting accessories; tube clamps etc.

Condensate pots up to 5 liters, come in 5 standard configurations with needle or ball valves.

Air distribution manifolds in 3 standard configurations, 2", 3", 4" diameter.

Prefabricated hookups:

for flow measurement — 5-valve direct mount manifold, ball valves, mounting accessories.

for pressure measurements — for low temperatures down to -200 ℃; for high temperatures in the range of 200 - 550 ℃; for cryogenic systems; for high viscosity media.

Hookups include integral valves designed to MESC specification.

Pressure gauge syphons designed to protect the instrument from pressure surges; oval flanges; swing adapters and other mounting accessories.

Condensate pots up to 5 liters, come in 5 standard configurations with needle or ball valves.

Air distribution manifolds in 3 standard configurations, 2", 3", 4" diameter.

Prefabricated hookups:

for flow measurement — 5-valve direct mount manifold, ball valves, mounting accessories.

for pressure measurements — for low temperatures down to -200 ℃; for high temperatures in the range of 200 - 550 ℃; for cryogenic systems; for high viscosity media.

Hookups include integral valves designed to MESC specification.

Pressure gauge syphons designed to protect the instrument from pressure surges; oval flanges; swing adapters and other mounting accessories.

(1) Compliance with international, Russian and industry standards.

(2) 100% output control and Fire Test according to API 607, BS 4368 Pt. IV, ASTM F 1387, MSS SP 99.

(3) A large range of manufacturing materials depending on the application.

(4) Interchangeable with similar products by other manufacturers.

(5) Competitive and at affordable price.

What does this mean for the customer?

Based on the experience and capabilities of VSP, the customer can always make an informed decision on the choice of a product in accordance with technical requirements and commercial conditions.

Availing of considerable experience in Instrumentation products, and understanding the market environment and position within the ecosystem, VSP sets itself the task of growth. Technical solutions by the new manufacturer of Instrumentation products as part of the VSP suppliers pool, based on the competitiveness of HAVI products — quality, reliability, compliance with standards — combined with affordability, will increase the efficiency of VSP project solutions for the end user.